Corrective actions should be made strategically and incrementally to the process.

Once you analyze data, you must make prompt corrective action to avoid catastrophes. Gathering data is only a small portion of what is required for top performance.

Act quickly to correct poor trends or conditions Targeting flow might give you an incomplete picture of the process characteristics.Ĥ. Trend pounds of solids in the aeration basin, waste activated sludge, and effluent TSS to determine plant sludge retention time (SRT).Note: Settling can also be affected by concentration alone. This will show how temperatures affect settling. Monitor the mixed liquor suspended solids concentration in the aeration basin and plant effluent total suspended solids to the temperature in the aeration basin.Check available flow data (raw flow, recycled flows, return activated sludge flow, etc.) in conjunction with dissolved oxygen concentration, which will give you a correlation to the impact of hydraulic loading to dissolved oxygen use.Maximize a plant’s SCADA data by following these tips: Trending data on SCADA terminals is a wonderful way to help identify positive and negative plant trends. Also, create a written sampling standard operating procedure to create consistency.ģ. Review sampling procedures, location labeling and operator techniques semi-annually. If operators do not use a uniform location and speed for the sludge judge test, it becomes difficult to trust data collected from shift to shift. Perform daily microscopic examinations of the aeration basin to monitor filamentous growth, and take prompt corrective action if abnormal conditions are observed.Ĭhoosing the right location for sludge sampling and clarifier core testing - commonly called sludge judge testing - is important for assessing a clarifier’s health.Alkalinity and nitrifying bacteria must be present - in the right ratio - to achieve complete nitrification. As the plant nitrifies, the potential for rising sludge increases because of denitrification in the clarifier. At extended aeration plants, monitor key parameters such as alkalinity, temperature and nitrification.The O&M provides guidance on the engineering capabilities of a biological system, therefore deviations can be detrimental.

#Clarifier ag talk manual

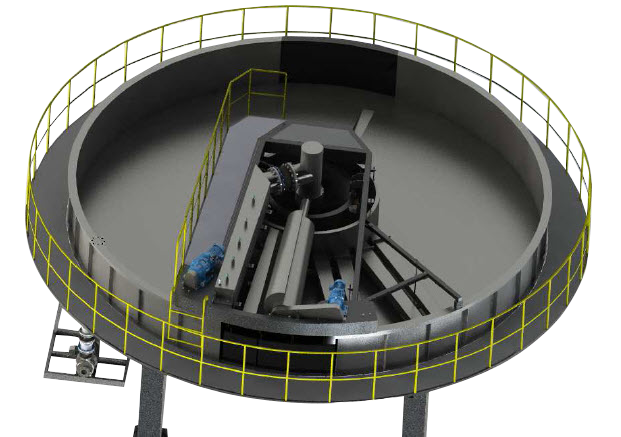

Check the plant’s operations and maintenance (O&M) manual to compare design criteria with current operations.If possible, automate the blower control to appropriately react to changing conditions of the hydraulic or organic loadings. Maintain an optimal dissolved oxygen level for your treatment train.Because poor settling solids can occur with biological process, be sure to check these process controls: Monitor the upstream biological system very closelyĬlarifier performance is married to the upstream biological system, whether the process is a trickling filter, rotating biological contactor, pure oxygen aeration or extended aeration. To maintain, a healthy secondary clarifier, follow these tips.ġ. Some wastewater facilities do not have a filtration system to capture total suspended solids released from the unit, which can put the system in violation of permits or inhibit disinfection systems. Its health is determined by upstream variables and the mechanical integrity of the clarifier components. The secondary clarifier is a vital part of every wastewater treatment plant. Get Treatment articles, news and videos right in your inbox! Sign up now.

0 kommentar(er)

0 kommentar(er)